Product Description

Automatic Glass Sealing Robot & Extruders:

1) Human-machine friendly interface, simple, user-friendly interface with simplified

thinking design, real-time display of glue pressure and various technical parameters,

easy to observe, simple and clear operation;

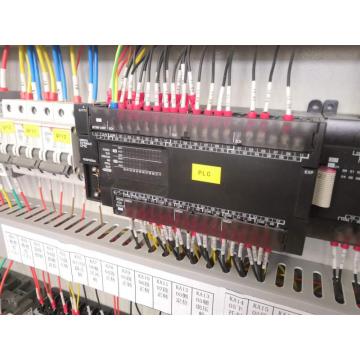

2) Electrical components, cable lines adopt imported famous brands and are durable;

3 )Automatically complete the connection glue, the operation is simple & convenient;

4) The machine parts are manufactured by CNC machining center, and the parts are

highly standardized, which can achieve interchangeability, improve the convenience

of maintenance, and ensure the long-term stable use of the equipment;

5) The assembly of the equipment adopts a pipeline type with high precision, which

ensures the long-term stable use of the equipment;

6) Servo control system adopts world famous brand (Yakawa, Japan), stable

performance, fast calculation speed, high precision of glue discharge;

7) The program has a memory function, and the glass parameters of different models

are called by one button;

8) The conveying wheel of the backrest plate adopts the mosaic design, and the glass

runs more smoothly;

9) Touch screen Internet communication, durable and fast;

10) The glass support module on the conveyor belt adopts a replaceable V-shaped block,

which is simple and convenient to replace after wear and has low cost;

11) Compact layout, weighted structure, small footprint, and more stable equipment;

12) Timing belt transmission makes the glass smoothly and positioning accurate;

13) Support two glass single cavity and three glass two cavity glass coating;

14)The sealing effect is perfect, the glass is coated with glue under the condition

of Neat, full and airless and the four sides are flat no need trimming;

15) Double glue supply system, one-button switching, can install two different glues

at the same time;

16) Automatic timing discharge function of glue to prevent the solidification and

clogging of the mixed rubber caused by the long interval between two pieces

of glass being glued due to manual operation;

17) The rubber mixing system adopts anti-blocking structure and is easy to clean.

Technical Parameters:

|

Max. Glass size

|

2500*4000mm

|

|

Min. Glass size

|

260*400mm

|

|

Glass thickness

|

12-50mm

|

|

Gluing speed

|

5-40m/min

|

|

Gluing Depth

|

3-18mm

|

|

Gluing pressure

|

35Mpa

|

|

Glass degree

|

6-8 degree

|

|

Power

|

14KW

|

|

Machine size

|

11600*3000*3450mm

|

|

Air pressure

|

0.5-0.7Mpa

|

.png) Contact Now

Contact Now